Rave Scientific

Nanotechnology Instrument Providers and Consultants

Rave Scientific

Nanotechnology Instrument Providers and Consultants

- You are here:

- Rave Scientific

- SEM Sputter Coaters

- Safematic Sputter-Carbon System

Safematic CCU-010 SEM Coating System

Overview

The Swiss made Safematic sputter and carbon coating system is a paradigm shift in the area of ease of use and throughput for electron microscopy sample preparation. This modular based system allows an end user to configure the system as a dedicated sputter or carbon only coating system, or both, and can be configured for low or high vacuum operation.

The patented automated carbon threading system allows for up to 70 unattended carbon depositions with no user intervention down to 1nm, providing the most advanced and versatile system design on the market today. Low vacuum systems have an in the field upgrade path to high vacuum operation, thus protecting your investment if your application requirements change. With the press of one button the CCU-010 recipe driven system produces reliable and reproducible results within minutes.

Safematic Unique Features and Applications

- Automatic Carbon Thread Transport-Our carbon head design allows for automatic threading during a coating run without the need to break vacuum or operator intervention. You will simply only need to initiate a coating sequence and return when the coating is complete.

- Adaptable Sputter Coating Head-If in the future you have a requirement for SEM coating of sputtered materials e.g,. Gold, Palladium, you need only purchase the interchangeable head that is exchanged for the Carbon thread head. You will then have the capability of carbon evaporation and sputtering materials.

- High Vacuum In the Field Upgrade Path-The Safematic offers an in the field upgrade path to a high vacuum system. High vacuum is required for the sputtering of materials such as Chromium and ITO (Indium Tin Oxide)

- Vacuum Pumps are Contained in the Chassis-All pumps for our LV and HV systems are conveniently contained in the chassis.

Safematic Automatic Carbon Threading System

Whether an end user needs to sputter, vaporize, or apply plasma treatment to carbon – you can configure the Safematic system for each of these applications by simply changing the process head. The Safematic system comes in two versions: The CCU-010 LV for low vacuum applications and the CCU-010 HV for high-vacuum applications. The modular concept of this product provides an in the field upgrade path, making it easy to convert the LV unit to a HV unit. The plug-and-play concept allows you to start up the device by yourself. You only need to connect the power supply and process gas.

SP-010 Sputtering Module

An integral part of the Safematic CCU-010 system is the SP-010 sputtering module. The housing of the SP-010 holds the chosen target. This allows our coating system to have a small form factor and yet offer all the features required for high quality sputter coating in a vacuum environment. The module fully integrates a magnetron, target, shutter, process pressure regulator and power electronics in a unique, robust unit that is guaranteed to be ready for operation and easy to maintain. An innovative interface with power and gas supply as well as signal transmission allows the modular system to be configured to work as a sputtering unit with just a single hand movement.

Highlights of the SP-010 Sputtering Module

- Electronically controlled process vacuum ensures stable pressure in the receptacle.

- Circular gas orifice ensures homogeneous process gas distribution.

- Detection and monitoring of splinter protection guarantees safe operation.

- Target cooling with temperature monitoring ensures smooth operation.

- Uniform electrical and pneumatic interface for use with basic units CCU-010 HV and CCU-010 LV.

CT-010 Carbon Thread Module

As a small, compact module, the CT-010 carbon yarn head has all the technical characteristics required for reproducible vaporizations and subsequent surface modifications. A newly developed automatic carbon yarn tracking system enables the unit to generate up to 50 carbon films without the user having to adjust the carbon yarn vaporizer. A high-performance combination of carbon coating and subsequent glow discharge treatment without interrupting the vacuum conditions ensures exceptionally efficient generation of hydrophilic carbon-carrying films.

Highlights

- An innovative, automatic tracking system (patent pending) manages up to 2m of carbon yarn, which is deployed using a spool.

- Pulsed electrical surges in ‘regular’ and ‘gentle’ mode meet every need, from rapid coating processes through to high-precision carbon coatings that are exceptionally easy on the samples.

- A process gas controller delivers the air for the glow discharge precisely on the surface of the substrate.

- Precise control of plasma output allows for a broad range of applications for modifying the surface properties of samples.

- Uniform electrical and pneumatic interface for use with basic units CCU-010 HV and CCU-010 LV

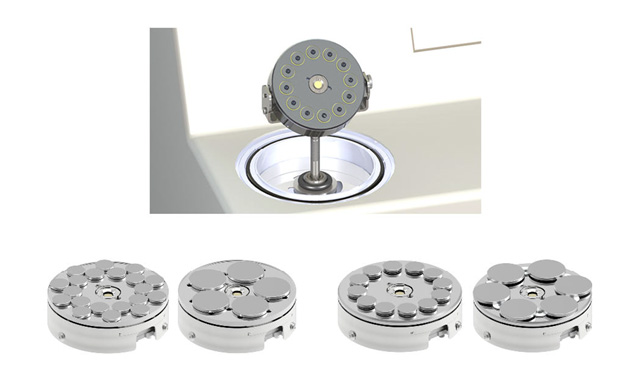

Safematic RS-010 Rotary Stage

Safematic PS-010 Planetary Stage

The above PS-010 planetary stage combined with the RS-010 rotary stage provides maximum flexibility. An integrated plug connection for the motor and layer thickness sensor is provided allowing the sample table to be exchanged in seconds. This stage delivers a universal, smooth adjustment of table height, tilt angle and rotational speed guaranteeing exceptionally homogenous films even on very jagged samples. Samples can be arranged optimally on the table thanks to the intelligent layout of the mounting holes for SEM stubs. The compact pancake design enables handy preparation and sample transport with a height of just 23 mm with an 80 mm diameter.

CCU-010 SEM Coating System

| RS-SM-CCU-010-LV | each |

Description: The CCU-010 SEM Coating System for low vacuum system operation. |

Request Quote / Info |

CCU-010 SEM Coating system

| RS-SM-CCU-010-HV | each |

Description: The CCU-010 SEM Coating system for high vacuum system operation. |

Request Quote / Info |

- SEM Sample Holders

- (Overview of Sample Holders)

- Angled and Tilt holders

- Bulk SEM sample holders

- Centering vise holder

- C-Square Muti Pin Holders

- Compact and universal vises

- EBSD sample holders

- FIB grid holders

- Filter Disk Holders

- Geological slide holders

- Gripping stub & stub vises

- Metallographic standard and reference sample holders

- Multiple Hitachi stub holders

- Multiple JEOL stub holders

- Multiple pin stub holders

- Multi XL holder large

- Non Magnetic Sample Holders

- S Clip Sample Holders

- Sample Clamp holders

- Small sample holders

- Small vise holders

- Soft jaw lining kit

- STEM imaging holder

- Swivel tilt sample holders

- TEM grid holders

- Transmission EBSD sample holders for TEM and FIB grids

- Universal sample holder kit

- Versa-Plate Adaptable Holder

- Versatile vise clamp holders

- Wafer holders

- XT stage extender strips

- °360°/90°off-set holder

- Metallographic Mount Holders

- Multiple Metallographic Mount Holders

- Sample Preparation

- Overview-Sample Preparation

- Applicators and Swabs

- Carbon Rods & Fibers

- Conductive Adhesives

- Cutting Tools

- Gloves & Cleaning Supplies

- Lab Scissors

- Non-Conductive Adhesives

- Plastic Transfer Pipettes

- Preparation Mats and Tiles

- Probes and Picks

- SEM Preparation Stands

- SEM-TEM Remote Plasma Cleaner - IBSS Plasma

- Sputter Targets

- Stainless Steel Mesh

- Supports and Substrates

- Tweezers

- Overview Tweezers

- High Precision Tweezers

- High Prec. Reverse Tweezers

- High Prec. Locking Tweezers

- High Prec. Mini Tweezers

- High Prec. Slim tweezers

- High Prec. Titanium Tweezers

- High Pr. Super Alloy Tweezers

- Cutting Tweezers

- SEM Stub Gripper Tweezers

- Cryo Grid Box Tweezers

- AFM/SPM cantilever tweezers

- AFM/SPM Disc tweezers

- Gatan 3View Pin Tweezers

- Wafer Handling Tweezers

- Plastic Tweezers

- Repl. Plastic Tip Tweezers

- Repl. ESD Ceramic Tip Tw.

- Repl. Ceramic Tips Tw.

- Value-Tec Fine Tweezers

- Value-Tec Ceramic Tip Tw.

- Value-Tec Fibre Grip Tweezers

- Value-Tec Strong Tweezers

- Tools

- Conductive SEM Coating Fluid

- PHP-4 Array Tomography Automated Kapton Tape Glow Discharge Cleaner

- MC-4 Multi-Modular Cleaner: UV Light, Plasma and Heating for SEM and TEM Samples

- EM Filaments

- SEM Sample Stubs

- Sample Stub Adapters

- JEOL SEM Supplies

- Overview JEOL SEM Supplies

- JEOL Tungsten Filaments

- Vacuum Storage-JEOL

- JEOL SEM Sample Holders

- JEOL Calibration Standards

- Desktop-NEOSCOPE SEM Supplies

- Desktop-NEOSCOPE SEM Holders

- JEOL Multi-Stub Holders

- JEOL Denka Lab6 Emitters

- JEOL Particle Analysis Holders

- JEOL SEM Stubs

- JEOL SEM Holder Adapters

- Sample Preparation Stands-JEOL

- Sample Storage-JEOL

- In-Situ Chamber Plasma Cleaner-JEOL

- SEM Stub Gripper-JEOL

- Hitachi SEM Supplies

- Overview Hitachi SEM Supplies

- Hitachi Calibration Standards

- HITACHI TM Desktop SEM Supplies

- HITACHI TM Desktop SEM Holders

- HITACHI -In Lens Sample Stubs

- HITACHI Multiple Stub SEM Holders

- HITACHI Particle Analysis Holders

- HITACHI M4 Stubs

- HITACHI SEM Holder Adapters

- HITACHI Tungsten Filaments

- Sample Preparation Stands-HITACHI

- Sample Storage-HITACHI

- HITACHI Sample Holders

- Vacuum Storage-HITACHI

- In-Situ Chamber Plasma Cleaner-Hitachi

- SEM Stub Gripper-Hitachi

- Zeiss SEM Supplies

- Overview

- Calibration Standards Zeiss

- Zeiss SEM Holders

- Zeiss Sample Preparation Stands

- Zeiss Tungsten Filaments

- Zeiss Denka Lab6 Filaments

- Zeiss Denka 174 Schottky Emitters

- Vacuum Storage-Zeiss

- Zeiss Pin Stubs

- Sample Storage-Zeiss

- Zeiss SEM Holder Adapters

- Zeiss Particle Analysis Holders

- In-Situ Chamber Plasma Cleaner

- SEM Stub Gripper Tweezers-Zeiss

- Thermo-FEI SEM Supplies

- Overview Thermo-FEI Supplies

- Calibration Standards-Thermo-FEI

- Dual Beam TEM Grids

- Gallium LMIS-Thermo FEI

- Dual Beam Pre-Cursors

- Dual Beam TEM Grid Holders

- Dual Beam Low Profile Stubs

- FEI Dual beam EBSD-3D sample Holder

- Dual Beam Gallium Sources

- FESEM FEI XL & Sirion Source Changes

- Non Magnetic Sample Holders

- Phenom SEM Supplies-Thermo-FEI

- Phenom Tabletop SEM Stubs & Sample Holders

- SEM Sample Holders-Thermo-FEI

- SEM Pin Stubs-Thermo-FEI

- Stage Adapters-Thermo FEI

- Thermo-FEI Tungsten Filaments

- SEM Stub Grippers-Thermo-FEI

- Particle Analysis Holders-Thermo FEI

- TESCAN SEM Supplies

- Overview TESCAN SEM Supplies

- Sample Preparation Stands-TESCAN

- Calibration Standards-TESCAN

- TESCAN SEM Sample Holders

- TESCAN Tungsten Filaments

- TESCAN Denka Lab6 Cathode

- TESCAN Denka 174 TFE Emitters

- TESCAN Particle Analysis Holders

- TESCAN SEM Holder Adapters

- TESCAN SEM Stubs

- Sample Storage-TESCAN

- Vacuum Storage-TESCAN

- TESCAN FIB-SEM TEM Lift-Out Grids

- TESCAN FIB-SEM TEM Grid Holders

- TESCAN FIB-SEM Pre-Tilt Low Profile Stubs

- SEM Stub Gripper Tweezers-TESCAN

- Desktop SEM Supplies

- Vacuum Supplies

- Light Microscopy Supplies

- Sputter Targets

- Sample Storage

- Overview

- Vacuum Sample Storage

- Inert Gas Sample Storage

- Rave-Tec Membrane Boxes

- Rave-Tec Sticky Gel Carrier Boxes

- Vacuum Glass Storage

- Pin Stub Storage

- Hitachi M4 Storage Boxes

- JEOL Stub Storage Boxes

- Desiccant Box

- Barrier Foil Ziplock Bags

- Wafer Carrier Trays

- Clear Plastic Boxes

- Small Cardboard Boxes

- Magn. AFM Disc Boxes

- Rave-Tec Field and lab sampler kits and boxes

- SEM Vacuum Transfer Shuttle for air-sensitive samples

- Vacuum Transfer Test

- SEM Stage Adapters

- Cryo Supplies

- Calibration Standards

- Dual Beam Supplies

- TEM Supplies

- AFM Supplies

- Lab Supplies

- SEM Sputter Coaters

- Safematic Supplies

- Metallurgical Supplies Overview

- Compact Smart Clip Metallographic Mount Holders for SEM

- Sample Embedding Clips

- Silicone Embedding Cups

- MET-C conductive hot embedding resin powder

- Laboratory Handheld Engraving Tool & Engraving Pen

- Rave-Tec temporary mounting waxes

- Vacuum Desiccators

- Diamond Polishing Paste-Metallurgical

- PTFE beakers-Metallurgical

- Metallurgical EBSD Holders

- SEM Stage Adapters Overview

- Vacuum Products

- Edwards Vacuum Supplies

- Pfeiffer Vacuum Products

- Pfeiffer Helium Leak Detectors

- Edwards Helium Leak Detectors

- Rotary Pump Vacuum Oil

- Apiezon Vacuum Grease

- Krytox Vacuum Grease

- KF / NW Vacuum Flange Connection Hardware

- Hysol 1C / Torr Seal Vacuum Epoxy Resin Sealant kit

- Rave-Tec stainless steel vacuum chamber for degassing

- Silver and carbon conductive vacuum greases

- Metal wires and materials for vacuum evaporation

- Rave-Tec KF/NW stainless steel vacuum bellows