3D microPREP Pro Desktop Laser Workstation

Overview

There is an increasing demand for faster alternative preparation techniques besides the traditional mechanical sample preparation and focused-ion-beam micromachining. It is well known that mechanical sample preparation is time consuming and is associated with a high cost for skilled personnel. While focused-ion-beam micromachining comes with an extremely high cost of ownership. The 3D microPREP™ Pro is a laser-based sample preparation workstation enabling high-volume material removal and sample preparation of metals, semiconductors, ceramics, and compound materials for microstructure diagnostics and failure analysis. The system can be used for a variety of semiconductor sample preparation applications, including in-plane geometries, bulk samples, cross-sections, box milling for diagnostics of electrical connections, and 3D chip-level characterization of through silicon vias (TSVs), or even complete systems-in-package (SiP). The integration of a pico-second laser ensures virtually no structural damage or elemental contamination of the material, thus minimizing the HAZ (Heat Affected Zone). In addition, microPREP™ PRO’s novel approach features substantially higher ablation rates in comparison to ion-beam-based processes.

The modular software design of microPREP™ ensures high flexibility for machining of samples for a broad range of microstructure diagnostics techniques. Based on machine-provided and customer-designed parameter-setups (recipes) microPREP™ PRO provides the best technology for sample preparation for:

- Scanning Electron Microscopy (SEM)

- Transmission Electron Microscopy (TEM)

- X-ray Microscopy (XRM)

- Atom-Probe Tomography (APT)

- Micromechanics

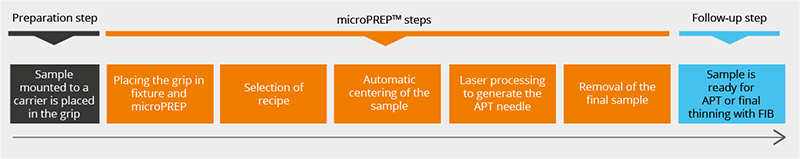

Based on patented processes, the microPREP™ PRO is ready to prepare samples for TEM, X-SEM, APT, and micromechanical testing in an almost entirely automated fashion. Making use of a rugged pulsed laser source, the process is characterized by very low running costs, suitability for semiconductors, metals, ceramics, as well as compounds thereof, and a very high targeted precision on the micron scale.

Sample Preparation Workflows - Application Results

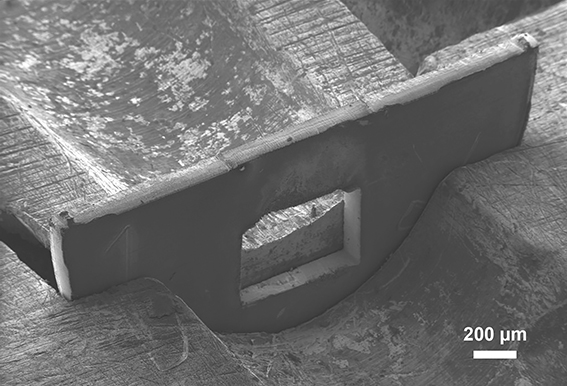

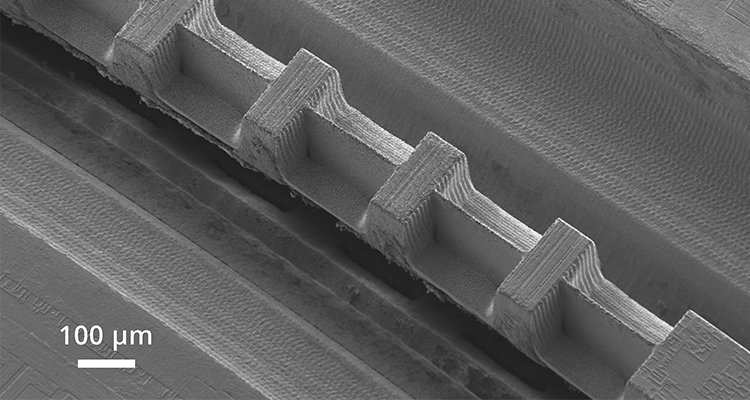

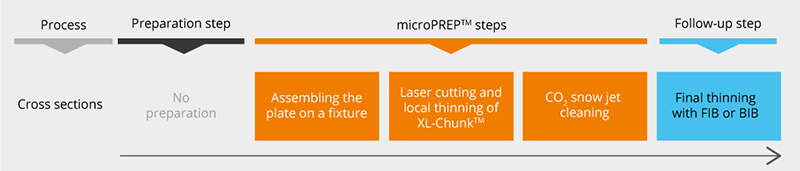

XL-Chunk

In order to achieve TEM-inspection of cross-sections, microPREP™ enables „push-the-button“- sample preparation of site-specific XL-Chunks™ by excavating and undercutting a well-defined volume from an arbitrary but flat sample surface. To further reduce FIB-capacity, XL-Chunks™ can be laser-thinned automatically to a few micron thicknesses at a region of interest according to customer’s needs, while providing order of magnitude time and cost savings compared to traditional sample preparation methods.

|

Application Results

Animation

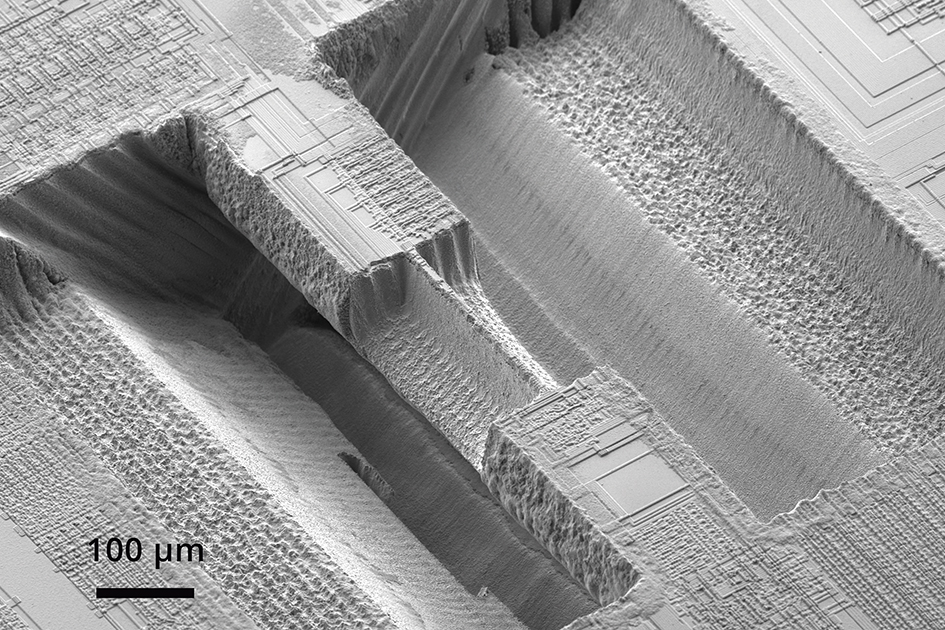

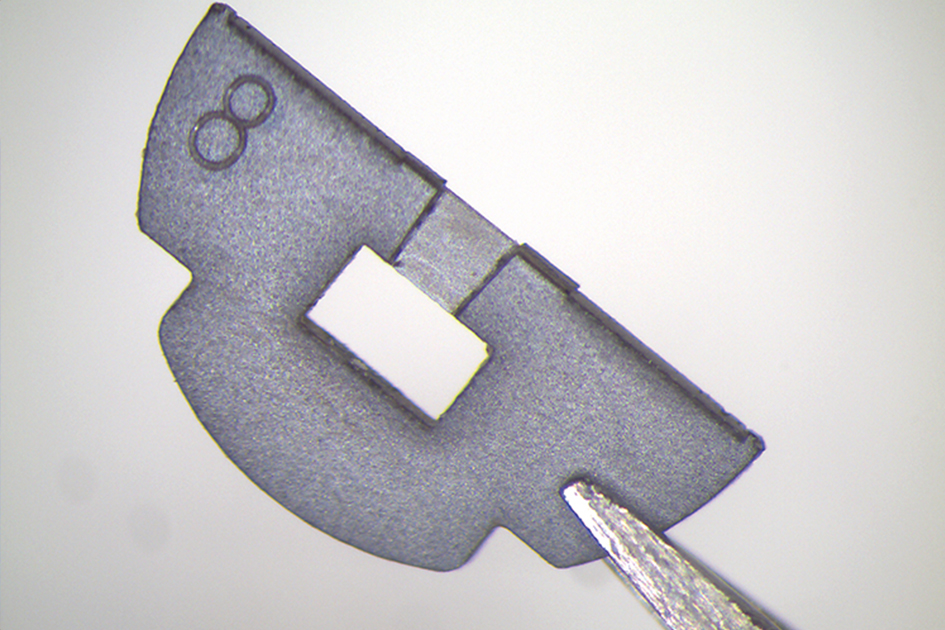

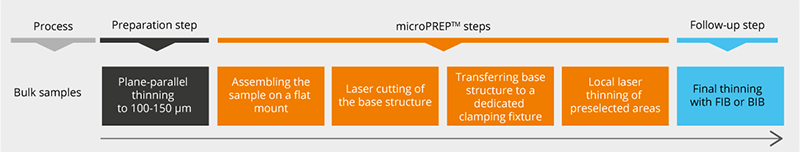

Cutting and Thinning

For investigation of bulk-samples by transmission electron microscopy (TEM), microPREP™ PRO offers an unique three-stage approach. This includes laser-cutting of a monolithic basic structure from a feedstock followed by subsequent laser-thinning to a few micron thickness and final thinning to electron transparency using either a broad ion beam (BIB) or a focused ion beam (FIB) while offering up to 10,000 times higher ablation rates and an order of magnitude lower cost of ownership compared to FIB.

Application Results

Animation

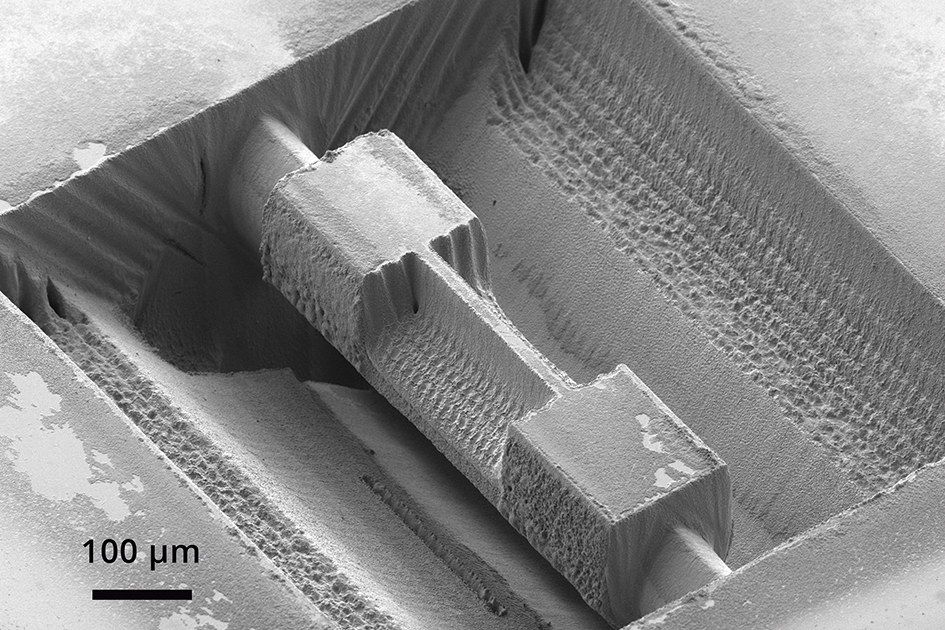

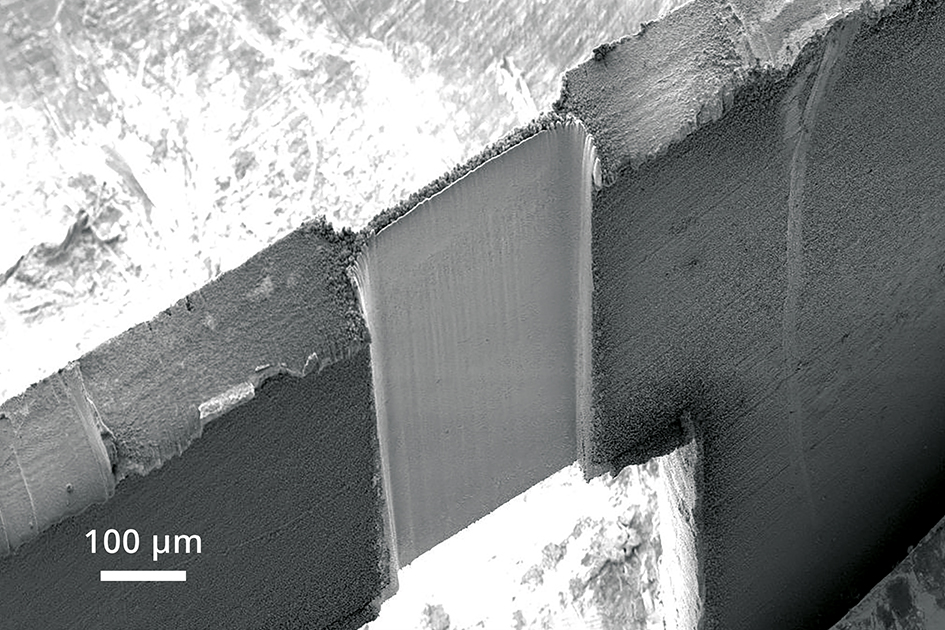

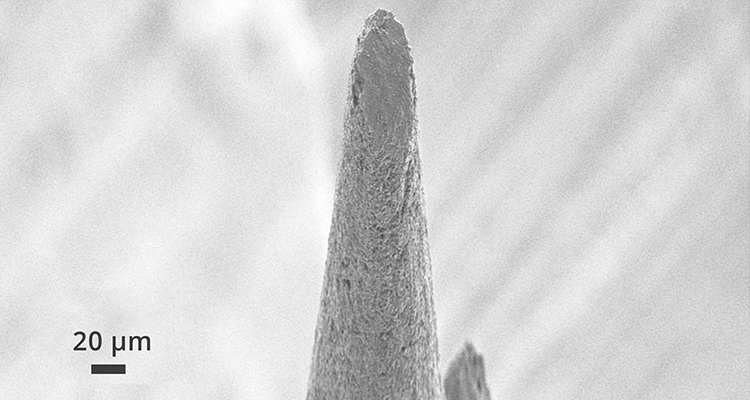

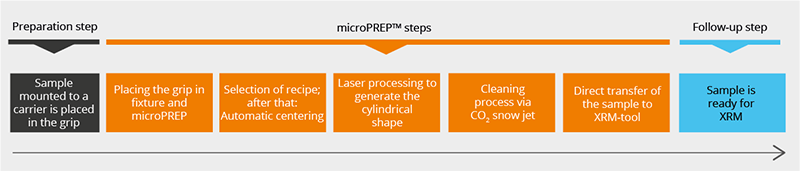

X-CT

For non-destructive 3D-characterization using high resolution X-ray microscopy (X-CT), samples of rotational symmetry with some 10 μm diameter are indispencible. While conventional FIB-micromachining would take days or weeks to prepare suitable samples, laser sample preparation of the same geometry using microPREP™ PRO takes less than 5 minutes.

Application Results

Animation

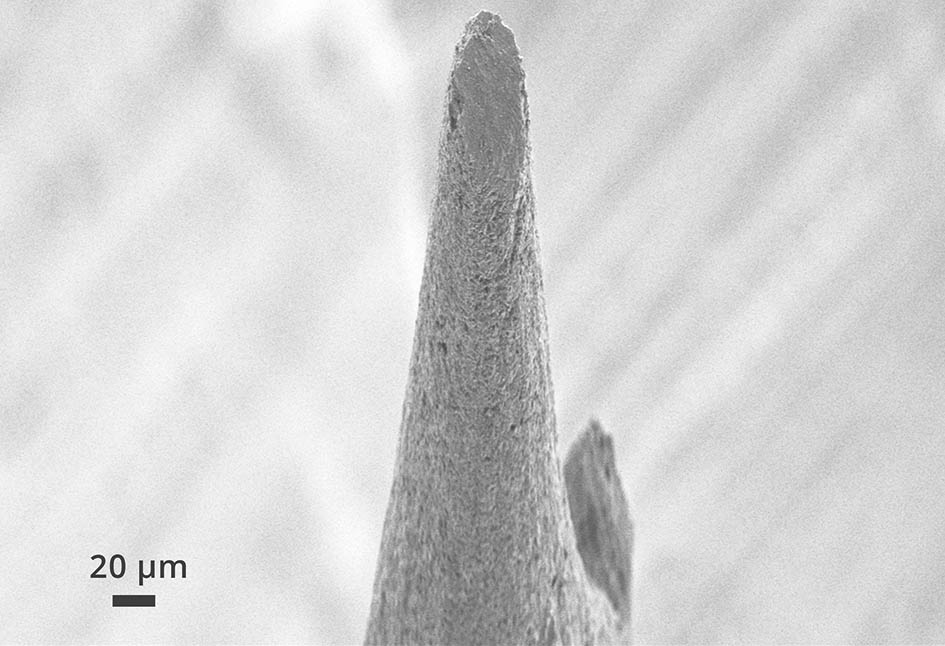

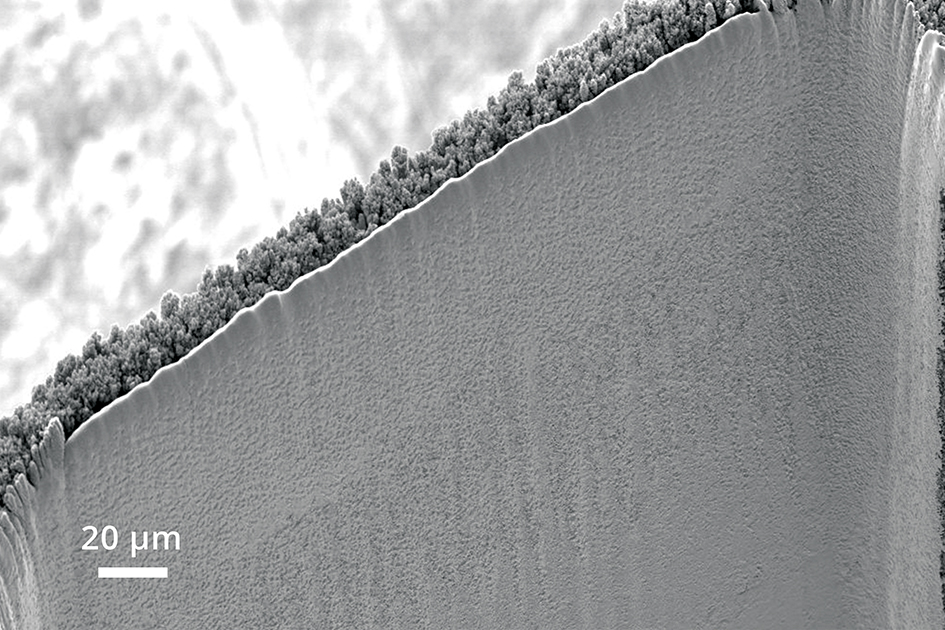

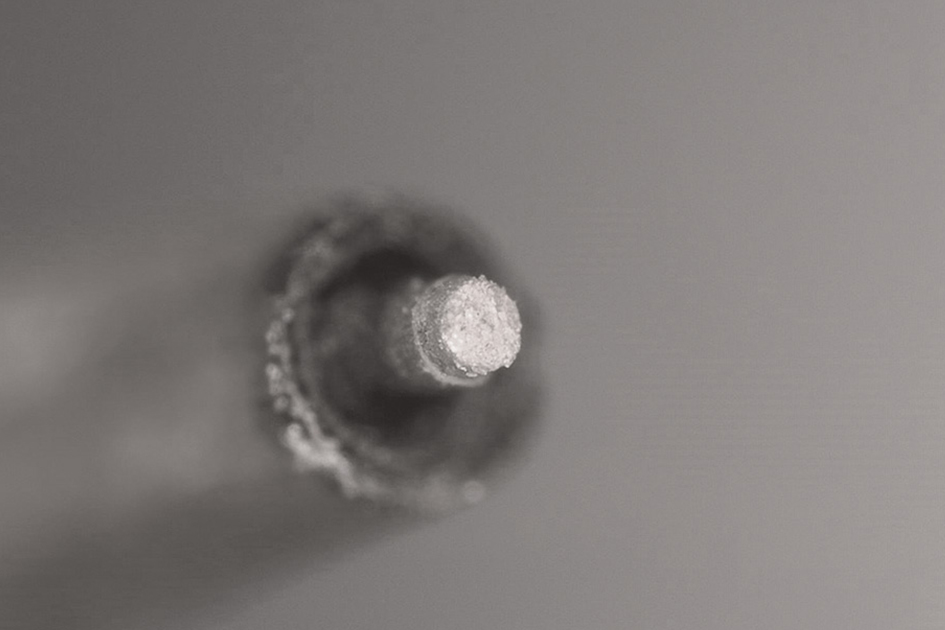

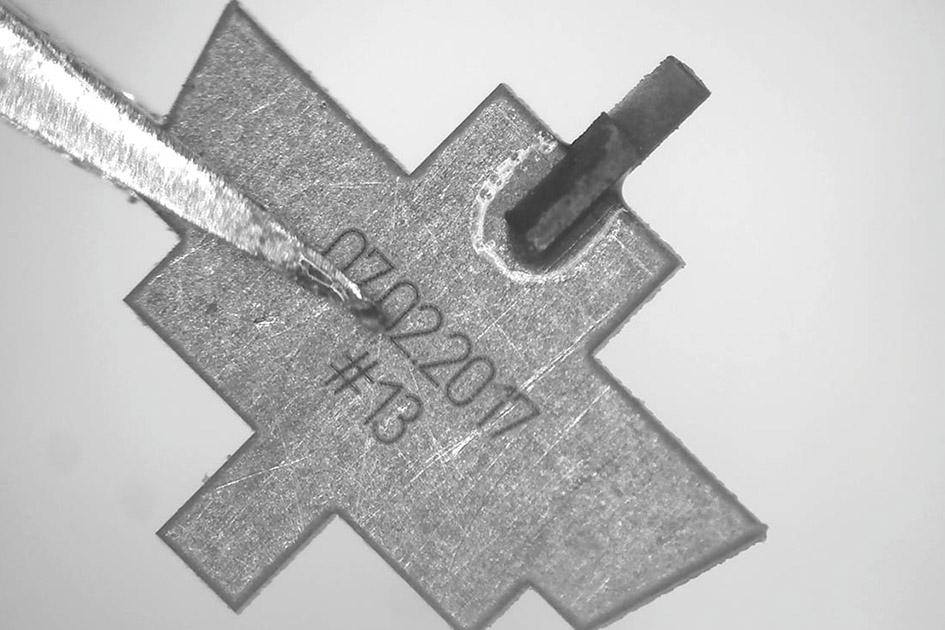

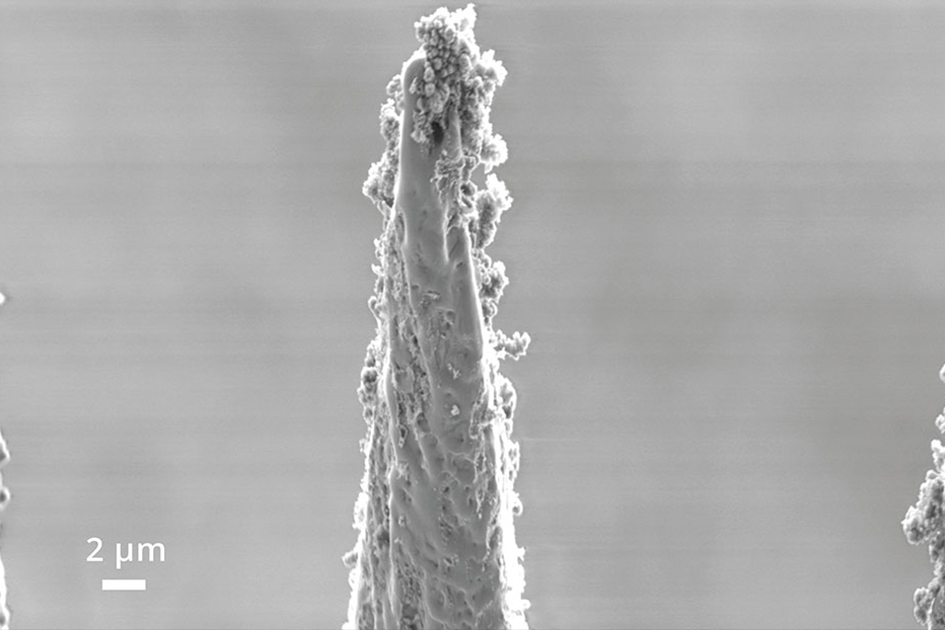

Atom Probe Tomography

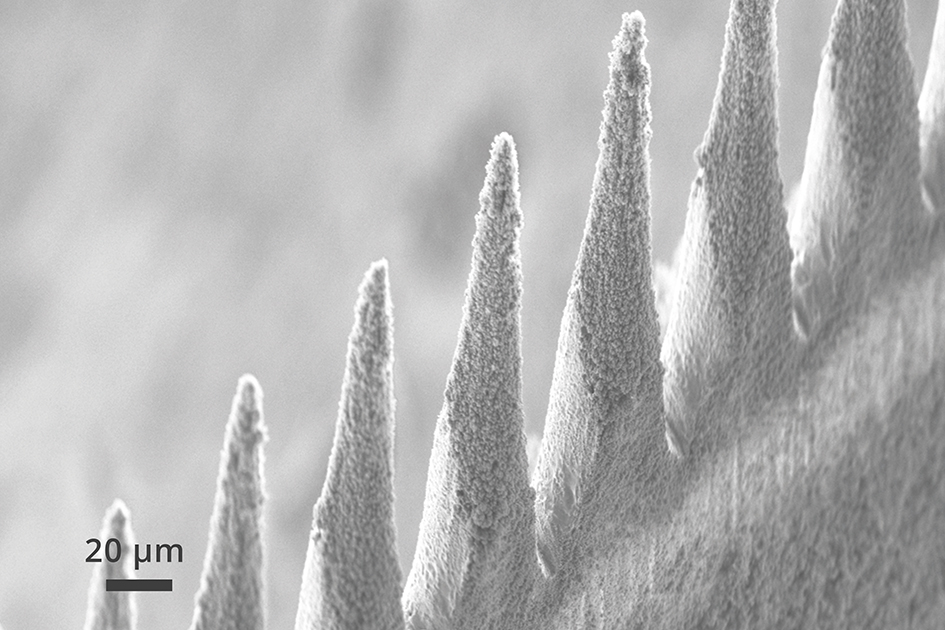

In order to improve sample preparation for atom probe tomography (APT), microPREP™ PRO enables side-specific cutting of dedicated APT-sample geometries and subsequent sharpening of tips to less than 15 μm diameter. Thus, microPREP™ not only helps to reduce FIB-capacity, but also improves yield and throughput for APT-measurements.

Application Results

Animation