Down Plasma Technology for Cleaning TEM Samples on Carbon Films

Introduction

With the advent of modern scanning/transmission electron microscopy (S/TEM) capable of higher resolution, better contrast,and faster throughput, it is imperative to ensure the cleanliness of the TEM sample under the ultrahigh vacuum conditions of the microscopes [1–5]. It is well known that sample contamination can severely deteriorate the quality of electron microscopy analysis of materials, especially as the sample regions of interest decrease in size. The adverse effects of sample contamination include obscuring the area of the sample being analyzed by buildup of a carbonaceous layer, interfering with focusing and astigmatismcorrection, and generating unexpected microanalysis signals [2, 3].

The metrology layout used for measuring the profile of a thread.

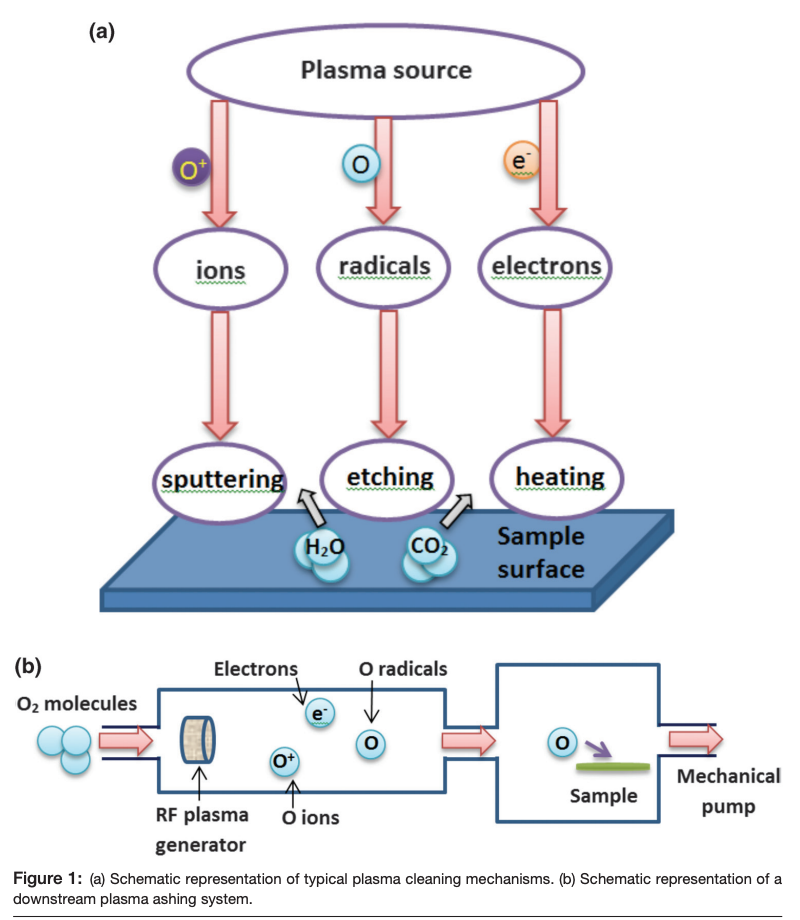

A variety of cleaning methods, including electron beam flooding, heating and/or cooling, ultraviolet light exposure, and plasma cleaning, have been developed to minimize sample contamination [4, 5]. Among them, plasma cleaning is considered the most effective way to prepare samples for electron microscopy. As shown in Figure 1a, a plasma can be described as an ionized gaseous state created by direct current (DC), radio frequency (RF), or microwave glow discharge, in which electrons, ions, and radicals coexist.

Related Products IBSS GV10 Chamber Plasma Cleaner IBSS MCA Mobile Plasma Cleaner