Calibrating a Scanning Electron Microscope (SEM)

Although modern manufacturing techniques have greatly improved the accuracy of SEMs, it is good practice to regularly check if the magnification shown on the SEM is still correct.

One should also take into account that magnification in the SEM changes with working distance. Magnification and the size marker shown on the SEM image are a best effort, but not always correct. The magnification error of an SEM can be in the range of 5-10%. Calibration becomes of utmost importance if measurements are made on SEM images.

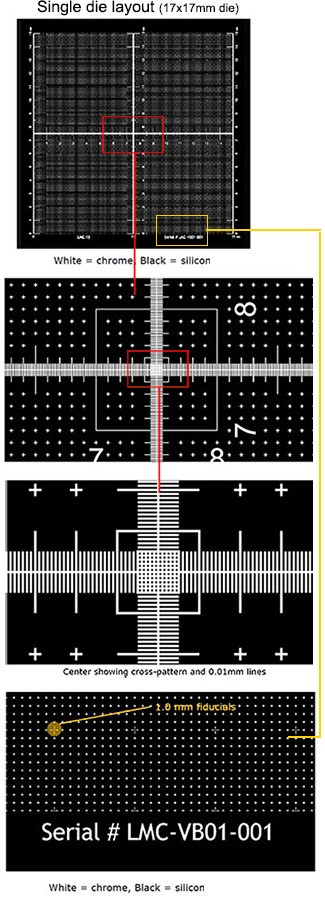

SEM calibration standards

The correct calibration feature (size) needs to be used for calibrating at a certain magnification. Available EM-Tec SEM calibration standards are:

- EM-Tec LAMS-15 for low magnification calibrations (15mm down to 10µm)

- EM-Tec M1 and M10 with 1 and 10µm patterns for medium range magnification calibrations

- EM-Tec MCS-1 for medium magnification range calibrations (2.5mm down to 1µm)

- EM-Tec MCS-0.1 for medium to high magnification calibrations (2.5mm down to 100nm)

Instructions on calibration

The magnification calibration standards comprise features, mostly lines with a known distance (pitch). It is best to select a calibration feature size compatible with the magnification used for imaging. A calibration for 1000x magnification is not valid for 100x or 10,000x magnification. When imaging is in the 2000x – 3000x magnification, calibrate at 2500x maginfication.

Calibration procedure steps:

- Select the calibration distance on the calibration standard – for example 10µm and make sure that the lines are vertical on the screen.

- Select the condenser lens setting and keep this setting throughout the calibration and imaging procedure

- Always remove lens hysteresis or approach always either from low or from high magnification

- Image the 10µm calibration feature to cover at least 10-20% in the middle of the image using an easy number like 2000 or 5000x magnification

- Measure the pitch of the lines horizontally (either center to center or left to left or right to right). Ideally this should be 10um if the system is calibrate correctly. In service or administrator mode, most SEMs offer the option to correct either magnification or size marker distance. To correct magnification or measured size multiply use the following formulas:

Magnification correction: Mcalibitrated = Mshown x Dshown/Dcalibrated

Measurement correction: Dactual = Dmeasured x Dcalibrated/Dshown

Where:

- Mcalibrated = Calibrated magnification

- Mshown = Magnification shown on SEM

- Dcalibrated = Actual feature size of calibration standard

- Dshown = Feature size of calibration standard shown on SEM

- Dactual = Actual (calibrated) distance in SEM image

- Dmeasured = Distance measured in SEM image

Example for magnification calibration:

Magnification of 5000x (Mshown) shows the 10µm distance(Dcalibrated) as 11µm (Dshown) The calibrated magnification (Mcalibrated) in reality is then: 5000x11/10 = 5500x. The magnification correction factor is 1.1

Example calibrated features sizes in images:

A feature in the same image as above is 25µm (Dmeasured). Previously, it has been determined that the 10µm on the calibration standard (Dcalibrated) was shown as 11µm (Dshown) on the SEM image (screen). The correct feature distance (Dactual) would be 25 x10/11 = 22.73µm. The correction factor for size measurements is this case is 0.91.

Notes for SEM calibrations:

- Only calibrate with a stable SEM; system and beam correctly saturated on for at least 30-60 minutes

- Calibrate at a specific working distance and SEM settings and keep these for subsequent measures. When changing working distances and/or settings, calibrate again.

- Always approach focus and condenser lens settings from the same side to counter hysteresis in the lenses; always from high to low or the other way around.

- The calibration standard contains a certificate; in the certificate you will find the calibrated feature sizes of the calibration features and the uncertainty (precision). For example, the nominal 10um feature might be calibrated at 10.05µm; use the 10.05µm for calibration purposes.

- The calibration uncertainty of an SEM is always equal or of higher uncertainty than that of the calibration standard.

- Check against image or stage drift; do not attempt calibration when drift is present.

- Provide a sufficient signal to produce clear images for calibration measurements

- Consider having the SEM calibrated by a qualified service engineer during maintenance