Rave Scientific

Nanotechnology Instrument Providers and Consultants

Rave Scientific

Nanotechnology Instrument Providers and Consultants

- You are here:

- Rave Scientific

- Rave Shop

- Sample Preparation Supplies

- Supports and Substrates

- Graphite Discs

Overview

When analyzing samples for analytical work in the SEM or for surface analysis the stubs used are nearly all made from aluminum and sometimes brass. This is fine for many applications if the sample is large enough and can be mounted directly on the stub. However, for small samples, powders, particles in solutions and fibers the finish and the material of the stub can interfere with imaging or X-ray analysis. Our graphite discs consists of high purity, soft spectral grade carbon. This material is softer and is less strong than the vitreous carbon materials. When handled with care they are still an excellent substrate for SEM imaging and X-ray micro-analysis. The carbon discs exhibit a low contribution for BSE imaging and a pure background with only the contribution of carbon for EDX and/or WDX analysis. The standard finish of our graphite discs are not as smooth as the vitreous carbon discs. Carbon discs are also more porous and more hydrophobic than vitreous carbon discs.

Carbon-Graphite Discs prevent interference.

To prevent interference of the stub surface you can place a carbon-graphite disc between the stub and the specimen and mount the specimen directly on these discs. Both discs varieties (also called planchets) form a protective shield.

Differences between vitreous carbon discs and carbon (graphite) discs.

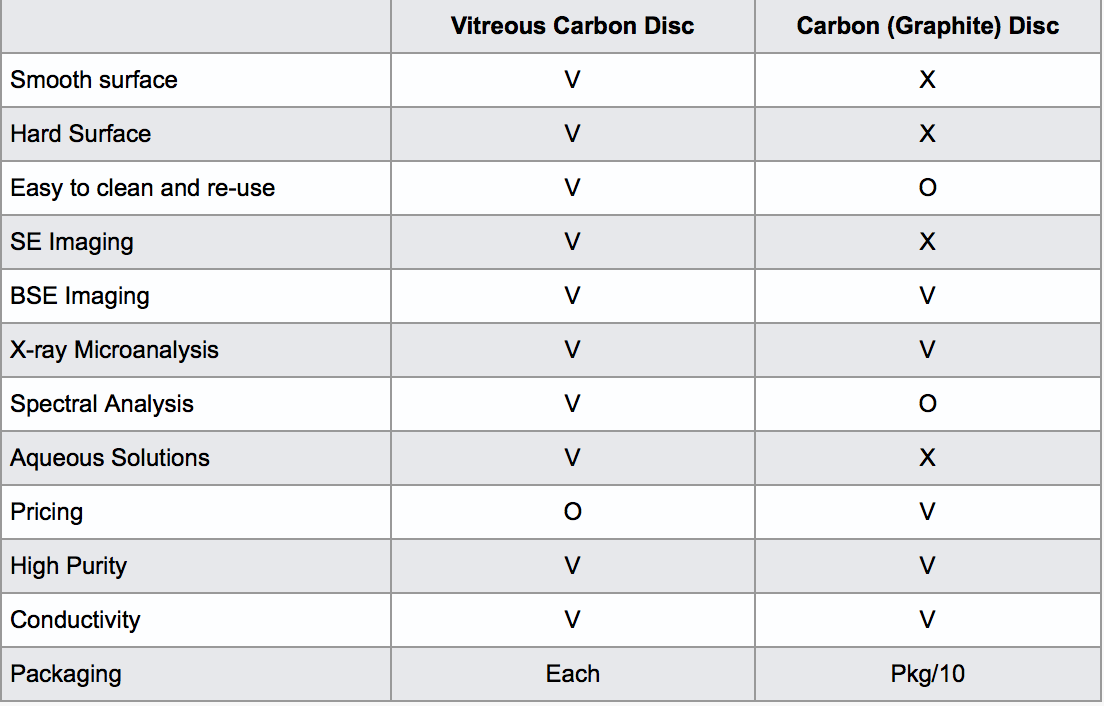

There are some differences between vitreous carbon and graphite discs. Vitreous carbon is superior in hardness, surface finish, mechanical and chemical stability but it is more expensive than carbon discs. The table below will give guidance to which material is best for the application at hand. Generally speaking, vitreous carbon is the better choice, but for less demanding applications carbon (graphite) discs will do just fine.

V= Best O= Medium X= Not Recommended

Surface finish of graphite discs

The standard ground finish of our graphite discs on one side is 0.80μm. The finish can be easily improved by lapping the discs on fine 10um grinding or lapping paper with water as lubricant. It should be noted that the surface roughness of the soft graphite material can be improved to 0.05μm or better.

Purity, handling and sizes of graphite discs

The high purity carbon used for the carbon planchets or discs only has impurities of less than 2ppm with 1ppm or less for each single element. The impurities can be B, Mg, Al, Si, Ca or Fe.The sizes available are 10, 12.7, 25.4 and 32mm diameters, all with a thickness of 1.6mm. These 4 sizes can be used on all popular SEM stubs and mounts. Since the material is relatively soft, we strongly suggest to glue the planchets on SEM stubs or mounts with a conductive carbon or silver glue. We would like to discourage the use of SEM stubs fully made of carbon; the material is soft so the pin can easily break off and during handling the soft carbon can easily shed material which can potentially cause contamination. Carbon discs glued on SEM stubs combine the advantages of the low contributing carbon background, low costs, easy handling and storage with the sturdy aluminum base. When the top of the specimen stub is completely covered by the graphite discs there is no imaging or analytical contribution of the supporting

- SEM Sample Holders

- (Overview of Sample Holders)

- Angled and Tilt holders

- Bulk SEM sample holders

- Centering vise holder

- C-Square Muti Pin Holders

- Compact and universal vises

- EBSD sample holders

- FIB grid holders

- Filter Disk Holders

- Geological slide holders

- Gripping stub & stub vises

- Metallographic standard and reference sample holders

- Multiple Hitachi stub holders

- Multiple JEOL stub holders

- Multiple pin stub holders

- Multi XL holder large

- Non Magnetic Sample Holders

- S Clip Sample Holders

- Sample Clamp holders

- Small sample holders

- Small vise holders

- Soft jaw lining kit

- STEM imaging holder

- Swivel tilt sample holders

- TEM grid holders

- Transmission EBSD sample holders for TEM and FIB grids

- Universal sample holder kit

- Versa-Plate Adaptable Holder

- Versatile vise clamp holders

- Wafer holders

- XT stage extender strips

- °360°/90°off-set holder

- Metallographic Mount Holders

- Multiple Metallographic Mount Holders

- Sample Preparation

- Overview-Sample Preparation

- Applicators and Swabs

- Carbon Rods & Fibers

- Conductive Adhesives

- Cutting Tools

- Gloves & Cleaning Supplies

- Lab Scissors

- Non-Conductive Adhesives

- Plastic Transfer Pipettes

- Preparation Mats and Tiles

- Probes and Picks

- SEM Preparation Stands

- SEM-TEM Remote Plasma Cleaner - IBSS Plasma

- Sputter Targets

- Stainless Steel Mesh

- Supports and Substrates

- Tweezers

- Overview Tweezers

- High Precision Tweezers

- High Prec. Reverse Tweezers

- High Prec. Locking Tweezers

- High Prec. Mini Tweezers

- High Prec. Slim tweezers

- High Prec. Titanium Tweezers

- High Pr. Super Alloy Tweezers

- Cutting Tweezers

- SEM Stub Gripper Tweezers

- Cryo Grid Box Tweezers

- AFM/SPM cantilever tweezers

- AFM/SPM Disc tweezers

- Gatan 3View Pin Tweezers

- Wafer Handling Tweezers

- Plastic Tweezers

- Repl. Plastic Tip Tweezers

- Repl. ESD Ceramic Tip Tw.

- Repl. Ceramic Tips Tw.

- Value-Tec Fine Tweezers

- Value-Tec Ceramic Tip Tw.

- Value-Tec Fibre Grip Tweezers

- Value-Tec Strong Tweezers

- Tools

- Conductive SEM Coating Fluid

- PHP-4 Array Tomography Automated Kapton Tape Glow Discharge Cleaner

- MC-4 Multi-Modular Cleaner: UV Light, Plasma and Heating for SEM and TEM Samples

- EM Filaments

- SEM Sample Stubs

- Sample Stub Adapters

- JEOL SEM Supplies

- Overview JEOL SEM Supplies

- JEOL Tungsten Filaments

- Vacuum Storage-JEOL

- JEOL SEM Sample Holders

- JEOL Calibration Standards

- Desktop-NEOSCOPE SEM Supplies

- Desktop-NEOSCOPE SEM Holders

- JEOL Multi-Stub Holders

- JEOL Denka Lab6 Emitters

- JEOL Particle Analysis Holders

- JEOL SEM Stubs

- JEOL SEM Holder Adapters

- Sample Preparation Stands-JEOL

- Sample Storage-JEOL

- In-Situ Chamber Plasma Cleaner-JEOL

- SEM Stub Gripper-JEOL

- Hitachi SEM Supplies

- Overview Hitachi SEM Supplies

- Hitachi Calibration Standards

- HITACHI TM Desktop SEM Supplies

- HITACHI TM Desktop SEM Holders

- HITACHI -In Lens Sample Stubs

- HITACHI Multiple Stub SEM Holders

- HITACHI Particle Analysis Holders

- HITACHI M4 Stubs

- HITACHI SEM Holder Adapters

- HITACHI Tungsten Filaments

- Sample Preparation Stands-HITACHI

- Sample Storage-HITACHI

- HITACHI Sample Holders

- Vacuum Storage-HITACHI

- In-Situ Chamber Plasma Cleaner-Hitachi

- SEM Stub Gripper-Hitachi

- Zeiss SEM Supplies

- Overview

- Calibration Standards Zeiss

- Zeiss SEM Holders

- Zeiss Sample Preparation Stands

- Zeiss Tungsten Filaments

- Zeiss Denka Lab6 Filaments

- Zeiss Denka 174 Schottky Emitters

- Vacuum Storage-Zeiss

- Zeiss Pin Stubs

- Sample Storage-Zeiss

- Zeiss SEM Holder Adapters

- Zeiss Particle Analysis Holders

- In-Situ Chamber Plasma Cleaner

- SEM Stub Gripper Tweezers-Zeiss

- Thermo-FEI SEM Supplies

- Overview Thermo-FEI Supplies

- Calibration Standards-Thermo-FEI

- Dual Beam TEM Grids

- Gallium LMIS-Thermo FEI

- Dual Beam Pre-Cursors

- Dual Beam TEM Grid Holders

- Dual Beam Low Profile Stubs

- FEI Dual beam EBSD-3D sample Holder

- Dual Beam Gallium Sources

- FESEM FEI XL & Sirion Source Changes

- Non Magnetic Sample Holders

- Phenom SEM Supplies-Thermo-FEI

- Phenom Tabletop SEM Stubs & Sample Holders

- SEM Sample Holders-Thermo-FEI

- SEM Pin Stubs-Thermo-FEI

- Stage Adapters-Thermo FEI

- Thermo-FEI Tungsten Filaments

- SEM Stub Grippers-Thermo-FEI

- Particle Analysis Holders-Thermo FEI

- TESCAN SEM Supplies

- Overview TESCAN SEM Supplies

- Sample Preparation Stands-TESCAN

- Calibration Standards-TESCAN

- TESCAN SEM Sample Holders

- TESCAN Tungsten Filaments

- TESCAN Denka Lab6 Cathode

- TESCAN Denka 174 TFE Emitters

- TESCAN Particle Analysis Holders

- TESCAN SEM Holder Adapters

- TESCAN SEM Stubs

- Sample Storage-TESCAN

- Vacuum Storage-TESCAN

- TESCAN FIB-SEM TEM Lift-Out Grids

- TESCAN FIB-SEM TEM Grid Holders

- TESCAN FIB-SEM Pre-Tilt Low Profile Stubs

- SEM Stub Gripper Tweezers-TESCAN

- Desktop SEM Supplies

- Vacuum Supplies

- Light Microscopy Supplies

- Sputter Targets

- Sample Storage

- Overview

- Vacuum Sample Storage

- Inert Gas Sample Storage

- Rave-Tec Membrane Boxes

- Rave-Tec Sticky Gel Carrier Boxes

- Vacuum Glass Storage

- Pin Stub Storage

- Hitachi M4 Storage Boxes

- JEOL Stub Storage Boxes

- Desiccant Box

- Barrier Foil Ziplock Bags

- Wafer Carrier Trays

- Clear Plastic Boxes

- Small Cardboard Boxes

- Magn. AFM Disc Boxes

- Rave-Tec Field and lab sampler kits and boxes

- SEM Vacuum Transfer Shuttle for air-sensitive samples

- Vacuum Transfer Test

- SEM Stage Adapters

- Cryo Supplies

- Calibration Standards

- Dual Beam Supplies

- TEM Supplies

- AFM Supplies

- Lab Supplies

- SEM Sputter Coaters

- Safematic Supplies

- Metallurgical Supplies Overview

- Compact Smart Clip Metallographic Mount Holders for SEM

- Sample Embedding Clips

- Silicone Embedding Cups

- MET-C conductive hot embedding resin powder

- Laboratory Handheld Engraving Tool & Engraving Pen

- Rave-Tec temporary mounting waxes

- Vacuum Desiccators

- Diamond Polishing Paste-Metallurgical

- PTFE beakers-Metallurgical

- Metallurgical EBSD Holders

- SEM Stage Adapters Overview

- Vacuum Products

- Edwards Vacuum Supplies

- Pfeiffer Vacuum Products

- Pfeiffer Helium Leak Detectors

- Edwards Helium Leak Detectors

- Rotary Pump Vacuum Oil

- Apiezon Vacuum Grease

- Krytox Vacuum Grease

- KF / NW Vacuum Flange Connection Hardware

- Hysol 1C / Torr Seal Vacuum Epoxy Resin Sealant kit

- Rave-Tec stainless steel vacuum chamber for degassing

- Silver and carbon conductive vacuum greases

- Metal wires and materials for vacuum evaporation

- Rave-Tec KF/NW stainless steel vacuum bellows